- Announcements

- BBQ and Food

- Cars

- Computing

- Cool Stuff

- Current Events

- Electric Vehicles

- Electronics

- Energy

- Flashahaulism

- Funny

- Government

- Hints and Tips

- History

- HVAC

- Induction heating

- Internet

- Lighting

- Misc

- Neon and other lighting

- Nuclear

- Personal

- Pets

- Philosophy

- Photography

- Power Generation

- Product Reviews

- Projects

- Q and A

- RV/Camping

- Science

- Tellico

Categories

Blogroll

Print This Post

Print This Post

Using an Induction Heater – MRO Operations

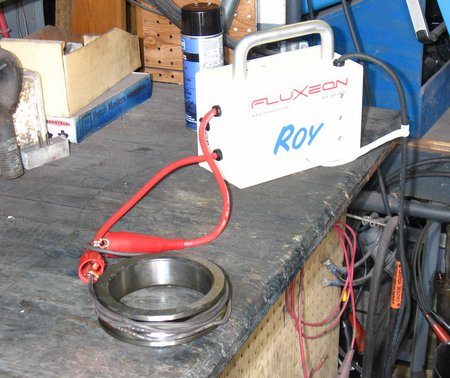

PermaLinkMRO (maintenance, repair, overhaul) is probably the largest field of application for a small, lightweight and portable induction heater such as Fluxeon’s® Roy induction heater. MRO encompasses everything from the auto mechanic to maintenance operations in large factories. Basically, anywhere guys and gals use tools to work on machinery.

In this article I’ll show some typical applications.

Removing devices from shafts or axles

A very typical MRO operation is to remove a pulley, sprocket or coupling from a shaft or axle. Typically this is difficult because of the initial tight fit of the pulley, a fit made tighter by age and corrosion. Heat is the universal loosener. The typical method of heating is to fire up the old acetylene torch and blast away. The object being heated is frequently overheated, is scorched and burned and the risk of setting fire to surrounding objects is high. With an induction heater there is no fire, no flame and no fire hazard. The object to be heated is heated rapidly and completely cleanly.

Here’s a typical example. A large taper-lock pulley is tightly fastened to the axle by corrosion and friction.

With the induction heater, heating the taper-lock hub is simple. Simply wrap several turns of suitably heavy wire around the hub, connect it to Roy and push the “heat” button.

As this photo shows, after only one minute, the hub is heated to about 350 deg F and that’s with Roy only running at about 600 watts – less than half power.

Shrink-Fit Bearings

Another typical MRO task is replacing the bearings in an electric motor, gear box or similar device. The bearing is frequently shrink fitted. Removal and replacement requires heating the bearing housing, preferably while not heating the bearing itself. Then the housing must be heated again to permit the new bearing to be dropped in.

Again, the typical heating method is to use an acetylene torch to heat the housing. Overheating, scorch marks and the risk of fire are typical hazards. And again, induction heat is flameless and clean.

This photo shows a motor end bell housing being heated in preparation to receiving the bearing. The process is fast and clean and since the induction coil itself does not get very warm, the coil can be held in place by hand, though we do recommend wearing work gloves!

This photo shows the inner race of a large bearing being heated prior to being fitted onto a motor shaft. If the bearing were of the pre-assembled type then the work coil would go inside the bore of the bearing. In either case, the heating is very fast – 15-20 seconds – and completely clean.

This photograph shows several things. First is that the work coil does not have to be in contact with the object to be heated in order to work. It can be of a convenient diameter. The second thing shown in this picture is that even pot metal or aluminum alloys can be heated. Not as rapidly as with ferrous metals but nonetheless heatable.

The applications possible in the maintenance or repair shop are nearly endless, from heating objects as shown here to brazing carbide tool bits to tool holders. The induction heater is one of those tools that, once you have it, you don’t know how you lived without it.

Note: A big thanks goes out to Jerry’s Electric Motor Service in Cleveland, TN for allowing me to take these photographs.

Posted by neonjohn on September 24th, 2010 under Cool Stuff, Induction heating

Leave a Comment