[1]I’ve been inundated with email from people wanting to know what is really going on in Japan. I decided to write this blog post to answer that question to the best of my ability. For those who don’t know my background, here’s a mini-resume:

[1]I’ve been inundated with email from people wanting to know what is really going on in Japan. I decided to write this blog post to answer that question to the best of my ability. For those who don’t know my background, here’s a mini-resume:

- Nuclear engineer with a specialty in high range radiation measuring instruments and techniques

- Trained by the Tennessee Valley Authority to operate this same type of reactor. (I chose not to become an operator because of the stresses involved.)

- Spent 2 years working all over the Browns Ferry Nuclear Plant (same GE Mk I units as in Japan) after the 1975 fire. I spent a lot of time inside the primary containment vessel replacing In-Core Instrumentation detectors and calibrating other instruments. Also spent much time in the reactor basement under the Torus calibrating various instrument systems.

- Spent 3 years working at TMI after the accident where I redesigned aspects of the undamaged unit’s radiation monitoring system and calibrated and supervised the installation of their post-accident radiation monitoring system. I also headed up a team that tested their emergency diesel generators for adequate emergency capacity.

In other words, I’ve been around.

In the Beginning

As we know, this started with a 9 magnitude earthquake which was about 5 times stronger than what the plants were designed for. The reactors shut down as designed and the core cooling systems kicked in, again as designed, powered by the diesel generators. That lasted about an hour until the tsunami hit. Again it was much larger than what the plant was designed to withstand. This flooded out the diesel generators and undoubtedly equipment on the lower levels of the plant. This is where things get a little murky

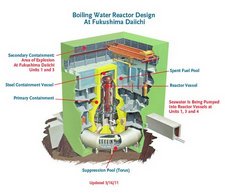

With only a couple of exceptions, every pipe that enters or leaves the primary containment pressure boundary (the yellow structure in the illustration above) has redundant valves both inside and outside the inner containment. The idea is that if there is some uncontrolled loss of control of either steam or feedwater (a broken pipe for example), the primary containment can be isolated.

Another planned-for emergency could be one or more control rod drives (that enter through the bottom on a BWR) breaking off, opening a hole in the reactor vessel.

The idea is that any steam released, either through relief valves or through a fault inside the primary containment would be conducted through the downcomers (the diagonal pipes that lead to the torus) and into the sparger system (the series of pipes shown in the torus cut-away) inside the torus that releases the steam underwater where it immediately condenses.

To make up for the loss of water, there are redundant HPSI (“hipsee”) and LPSI (“lipsee”) pumps (high and low pressure safety injection pumps) located in alcoves off the reactor building under the torus (not shown). There are 3 of each variety of these pumps. 2 are steam driven and one is driven from the station’s 250 volt DC battery.

A pipe comes straight off the reactor with no isolation valves and only one spring operated normally open block valve to the turbine. This block valve is held closed by a signal from the control system. If the control system tells it to or if power is lost, springs snap the valve open and the turbine starts.

The turbine is a Terry pelton (paddlewheel) unit that can withstand abuse ranging from water slugging to solid material (say, failed fuel) impact. It drives a pump that takes suction directly from the bottom of the torus and injects water through a series of spray bars directly on top of the core (not shown in the illustration).

The pumps require no electrical power (hydraulic governor) and one pump is adequate to cool the reactor. The HPSI runs until the pressure becomes too low for efficient operation. Then the LPSI takes over and cools the reactor until there is no more steam.

So the water makes a closed loop. From the torus to the HPSI, to the core where it turns to steam, to the HPSI turbine and back to the torus where the exhaust steam is condensed. The torus contains about 1.5 million gallons of water and is designed to

be a heat sink for several days (the number is now in fuzzy memory but I believe that it is 7 days).

The Torus is in turn cooled by the Residual Heat Removal system. The RHR is a closed loop cooling system containing demineralized water. It cools the torus and the reactor after steam pressure is reduced to 15 psi or less and during cold shutdown. It, in turn, is cooled by the Service Water system. The SW system is simply lake or sea water pumped throughout the plant for general cooling.

What I don’t understand is why the HPSI system didn’t kick in on these reactors. One possibility is that the japs left this system off, though it is very unlikely. At that point GE was selling standardized nuclear plants. You did the site selection and they came in and built a standard plant. That’s how they build Browns Ferry for $300 million (Sequoyah, which TVA custom-designed came in at a cool $9 billion) I’ve spent a lot of time trying to determine this detail but cannot find it, at least not on the net.

The only thing I can figure is that the system was damaged during the quake. In the BFNP, the steam line to the HPSI pump has a vertical run that is perhaps 75 ft long. It is snubbed in several places with earthquake snubbers (shock absorbers on steroids) but that run could still be subject to large deflections if the frequency was just right.

Maybe enough to break it. One of the things that I worked on at BFNP was tuning out such resonances in the emergency cooling system piping and pumps.

The turbo pump itself is skid mounted and factory fabricated and supported on spring mounts for earthquake resistance. I imagine that a shake many times what it was designed and tested for could break those mounts and tear the platform free.

Who knows? We probably won’t ever know on that one. The containment basement at TMI is still too hot to enter 30 years later because of all the cesium that soaked into the concrete. I don’t expect this one to be any different. Maybe someday a robot can have a look.

Without cooling

Back to the point where the power failed. Without a supply of feedwater to cool the core, the reactor vessel quickly boiled dry and exposed the fuel to the environment (steam). The actual uranium fuel is in the form of a ceramic oxide with a melting point greater than 3000 deg C (5400 deg F) The pellets of this oxide are contained in tubes made of an alloy of Zirconium called Zircalloy. Zirconium is used because it is strong, corrosion resistant and transparent to neutrons.

When Zircalloy reaches a certain temperature, it will start reacting or “burning” in steam, stripping away the oxygen atom from the water and releasing hydrogen. That is where all the hydrogen has come from. The fuel in units 1 through 3 got hot enough to burn off the Zircalloy and release hydrogen along with fission gases normally contained within the rods.

When the operators saw the first hydrogen, they knew that the core was toast. That and the continuing blackout make the normally difficult decision to cool with seawater easy. The decision to use seawater is difficult because the salt in the water essentially destroys the stainless steel that makes up most of the reactor plumbing. In other words, the plant is ruined for further use. Since the plant was already ruined, using seawater was a sound decision.

The problem was that the seawater was not getting to the core, or at least not much of it was. The cores remained hot enough to continue making hydrogen. Thus the multiple explosions. The explosions themselves were little more than window dressing for the evening TV news, as only the sheet metal cover over the refueling floor (the part where the crane is in the illustration) was blown away. Likely there was no damage to plant components themselves.

The operators had to vent the steam and hydrogen to avoid over-pressurizing the primary containment structures. Carried along in this stream were radioactive noble gases, the primary ones being Xe-133 and Kr-85. These are fission products produced as the reactor operates and result from the uranium atoms splitting.

Xe-133 is a rich gamma ray emitter and so can deliver a high dose even in small quantities. Fortunately it has a short half-life of 5.25 days so it is constantly decaying away. In about 5 days there will be only half as much as before.

The other isotope is Kr-85. It is a beta particle emitter with a rare gamma ray. The betas can’t penetrate the skin so the primary hazard is inhalation. It has a long half-life of about 10 years so it’ll hang around inside the reactor building when all the other gases have decayed away.

Physically both gases are heavier than air and tend to hug the ground around the reactor. They account for the reports of widely varying high radiation in the area where the emergency workers are operating.

Once mixed with air, they rapidly are diluted. The very low doses measured at some distance from the site are from these gases being blown by the winds.

Iodine

One of the mass media’s whipping boys is always the alleged danger of I-131, another fission product. They again have the public whipped into a frenzy and one could not buy a potassium iodide pill for love nor money even here in the States. This is one of the craziest parts of this whole evolution.

Elemental iodine is a solid at room temperature but has a high vapor pressure and easily vaporizes when warm. Because of that the (willfully) ignorant “experts” go on and on about how bad the iodine release is going to be if the core(s) melt. Clue: The cores have melted but no iodine. Why?

Well, we learned at TMI that the iodine and the cesium (another fission product) combined to form the solid cesium iodide. This solid either settled out on surfaces inside the containment or dissolved in the water in the sump and remaining in the reactor coolant system. Only a tiny, vanishingly small amount was actually released when the TMI containment had to be vented. Probably a little dust containing the cesium iodide.

Meanwhile uncounted people will be making themselves sick by gulping down the KI pills. Here’s a good comment [2] on that by a medical research expert.

Spent Fuel Pit

The latest hysteria as I write this concerns Unit 4’s spent fuel pit and the “fire” that appears to be burning in it. From information that I can gather, the pit was damaged in the shake and the water that keeps the spent fuel cool has gradually leaked out. The fuel is much less energetic than that in the reactors because it has been out of the reactor for about a year. Still it produces heat that has to be carried away.

I’m not familiar enough with the spent fuel in that pit to know for sure but it is possible that it could get hot enough to again react with the residual water and “burn”, releasing hydrogen. This should not be a problem this time since the roof of the building is already gone so the hydrogen simply zooms up, up and away.

End Result

This will be another TMI, only larger. Let’s review what happened at TMI. Through operator error and instrument malfunction the core was allowed to remain uncovered until it melted. Yep the dreaded “core melt”. But instead of industriously heading for China like the critics and the movie allege, the molten core hit water remaining in the bottom of the reactor vessel and quenched itself. It didn’t even scar the inside of the reactor vessel.

At TMI:

- Nobody was killed or even injured

- No member of the public was exposed to radiation above the standard (very conservative) guidelines

- No contamination reached the plant boundary.

- No contamination reached the un-damaged Unit 1 plant located beside Unit 2.

- The only harm was caused by the government and media-whipped hysteria. At least one person died in a traffic accident during the evacuation, an evacuation that was not necessary.

- No one other than GPU stockholders were harmed in any way.

Unfortunately the plant construction moratorium that happened in the wake of TMI resulted in our energy dependence being set back about 30 years, resulted in a couple of oil wars and leaves us even more dependent on foreign oil and natural gas than ever before. I sure hope that this doesn’t happen again this time.

In Japan at Fukushima Daiichi #2 and possibly #3, it appears that the core has melted through the reactor vessel. No big deal off-site. It’s stopped by water in the primary containment vessel. So the clean-up is going to be a bit more messy than TMI. Other than that, it’s going to be exactly like TMI. All the damage will be confined to the plant sites. No public will be harmed by the accident. Some folks will be injured or perhaps killed in the hysterical evacuations. The only harm will be financial to the utility and the evacuees. Let’s hope that it doesn’t set back Japan’s nuclear plans like TMI did the US’s.

(Sometimes) Reliable Information

Here are some places that I check regularly for information.

- Nuclear Energy Institute [3] – They are keeping their site updated in near real-time. The information seems accurate and is certainly consistent with what I know.

- World Nuclear News [4] – Also a good site. A little more technical but a bit less timely than NEI

- IAEA [5] – The International Atomic Energy Agency is one of the most self-absorbed and self-important agencies of the UN. Nonetheless, they are keeping their news site fairly current. There’s a bit more politics involved in this reporting but the facts can usually be sorted out.

Conclusion

Well, that’s about it for my nuclear brain dump. I do want to take a moment to say a prayer for the perhaps 20,000 casualties of the quake and tsunami. That’s the real story and not some happening at a nuclear facility. The mass media should be excoriated for practically ignoring this aspect while braying like jackasses about the nuclear situation.

That’s all, Folks.